Trade Ideas Blog

Rock your Stocks off: How National Rock and Roll Day Echoes Stock Market Rhythms and Investment Strategies

By: Katie Gomez While many Americans focus on celebrating Independence Day in July, there’s another lesser-known observance that closely follows…

Read MoreDown the Rabbit Hole: The Importance of Imagination as Trader: How Alice in Wonderland Day Can Boost Your Investment Strategy

By: Katie Gomez While July 4th is widely celebrated as Independence Day in the U.S., it also marks a lesser-known…

Read MoreMirror, Mirror on the Wall: How Self-Compassion Boosts Trading Success & Happiness

By: Katie Gomez While the invention of unique national holidays has taken over our calendars in the last decade, I…

Read More4 Stocks That Could Spark Fireworks This Fourth of July

By: Katie Gomez As Americans, it’s easy to see why we are so enamored with the sights of fireworks on…

Read More4 Crucial Aspects of Technical Analysis for Day Traders

By: Shane Neagle Understanding technical analysis is crucial to making wise judgments and staying ahead of market moves in the…

Read MoreMastering the Art of Stock Selection: Proven Strategies for Successful Trading

In the fast-paced world of stock trading, the key to success lies in selecting the right assets to trade. While…

Read MoreSummer Stock Trading 101: How to Plan Your Stock Trading Portfolio Like Your Summer Vacation Itinerary

By Katie Gomez Although most of us avoid being the ones stuck planning the itinerary for vacation, without some semblance…

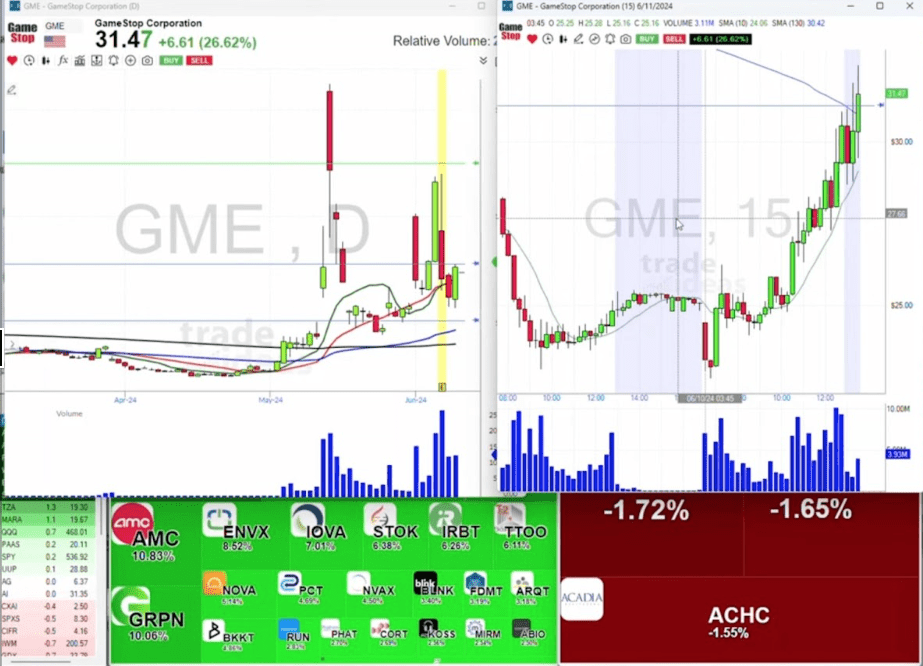

Read MoreMastering the Art of Trading Around: A GameStop Case Study

In the thrilling world of stock trading, the concept of ‘trading around’ has gained significant attention, especially in volatile stocks…

Read MoreMindfulness and Mediation: The Underestimated Keys to Becoming a Successful Trader

By Katie Gomez When we overload our brains with too much information, we either experience burnout or a breakdown. We…

Read MoreThe Father’s Day Financial Gift: Investing Lessons from Dad for a Lifetime of Financial Success

By: Katie Gomez Father’s Day is a time to celebrate the men who have guided, supported, and shaped us into…

Read MoreUnveiling The Power of My Favorite Scan: How DWAC Made the Trade Great

Hey there, fellow traders and market enthusiasts! It’s Barrie Einarson from Trade Ideas, back with today’s edition of “What Makes…

Read More6 Strategies for Maximizing Profits in Day Trading

By: Shane Neagle Have you ever pondered what elevates certain day traders above the rest? Within the stock market’s ever-changing…

Read More4 Key Risk Management Factors When Day Trading

Written by Shane Neagle Can traders really navigate the unpredictable waters of day trading and come out ahead? Absolutely, and…

Read MoreMicron Drops After Forecasting Wider Than Expected Loss

Written by Guest Contributor, Shane Neagle While Micron Technology (NASDAQ: MU) reported adjusted revenue for its fourth fiscal quarter that…

Read MoreDaily "What Makes This Trade Great"

SOC: What Makes This Trade GreatSeptember 20, 2024

Hey traders, Barrie Einarson here with today’s edition of What Makes This Trade Great. Today, we’re taking a look at…

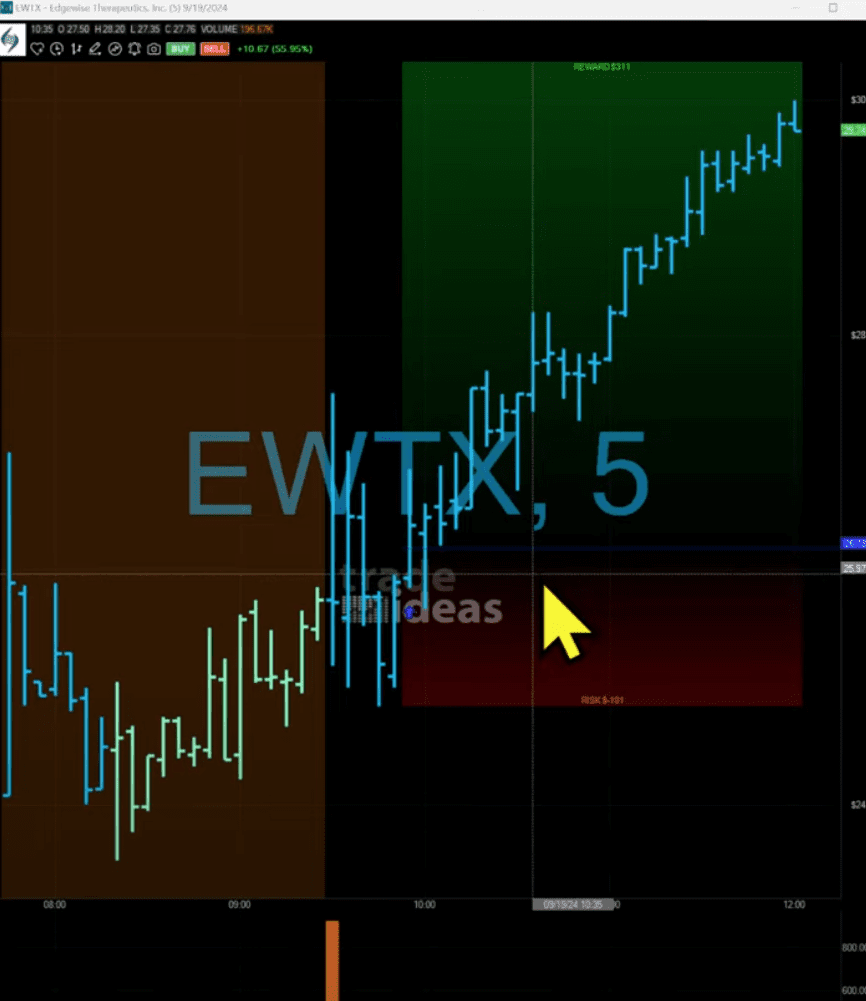

Read MoreEWTX: A Big Win Spotted by AI

Hey everyone, Barrie Einarson here with another exciting trade breakdown. Today’s star performer is EWTX, and what a ride it’s…

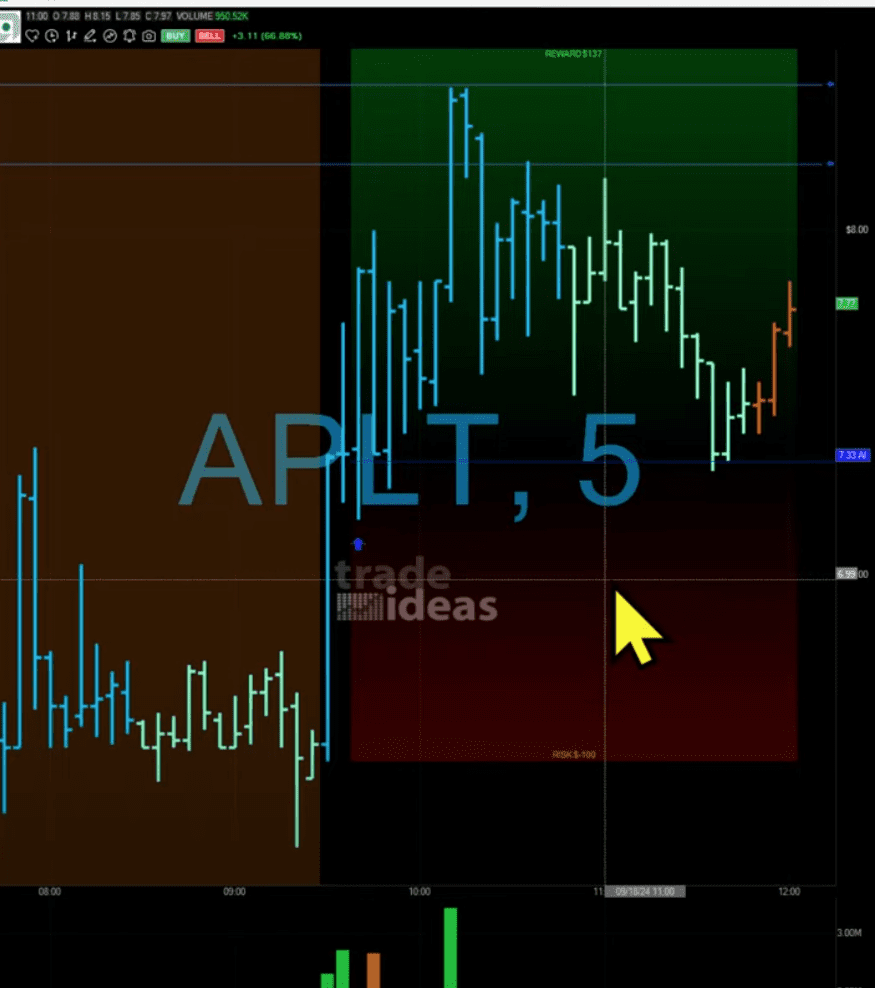

Read MoreA Day of Opportunity with APLT

Hey traders, Barrie Einarson here with today’s breakdown on what made APLT such a great trade. On a day when…

Read MoreWhat Makes This Trade Great – A Look at CAPR

Hello traders, Barrie Einarson here from Trade Ideas with another edition of “What Makes This Trade Great.” Today, we’re diving…

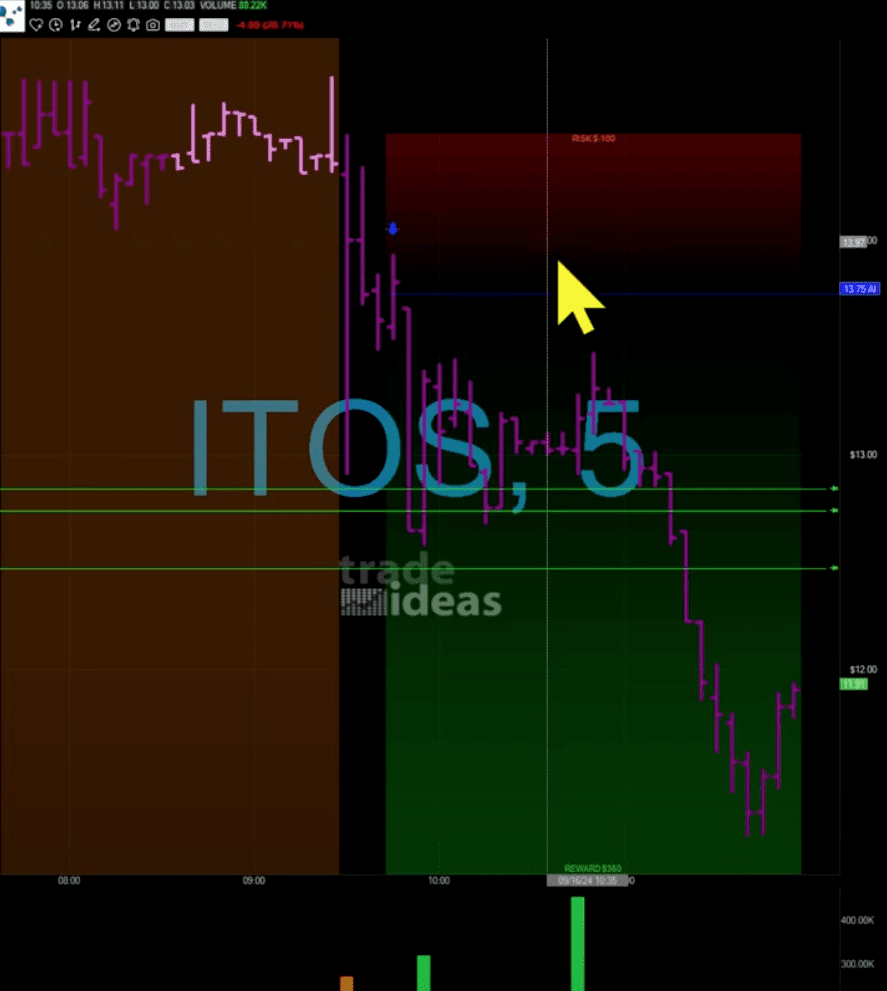

Read MoreTrading Insights from Barrie Einarson – Navigating a Tricky Trade with ITOS

Hello, fellow traders! Barrie Einarson here, sharing some insights from today’s session with ITOS. To Subscribe: https://go.trade-ideas.com/SHQUse Promo Code BARRIE15 for…

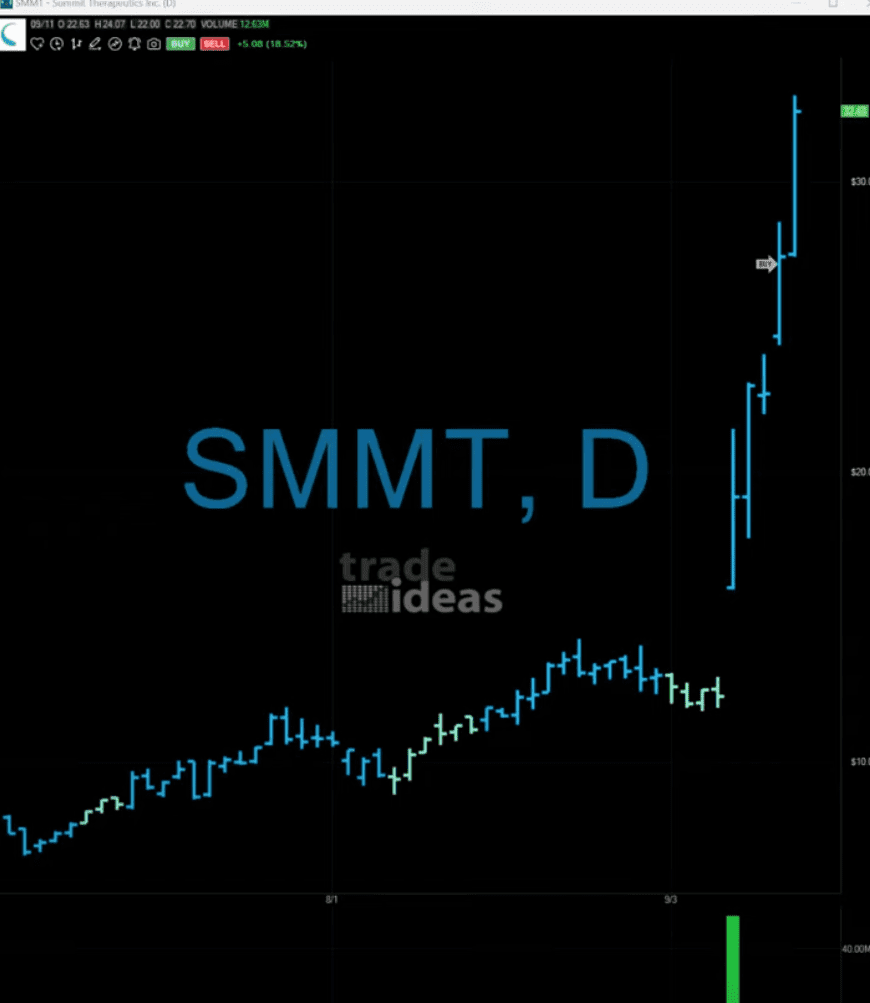

Read MoreWhat Makes This Trade Great: SMMT and TIL — A Tale of Two Biotechs

Hello traders, Barrie Einarson here from Trade Ideas with today’s edition of “What Makes This Trade Great.” Today, we’re diving…

Read MoreHow I Found the Trade of the Day with LOVE

Hey traders, Barrie Einarson here from Trade Ideas, back with another installment of “What Makes This Trade Great.” Today, I’m…

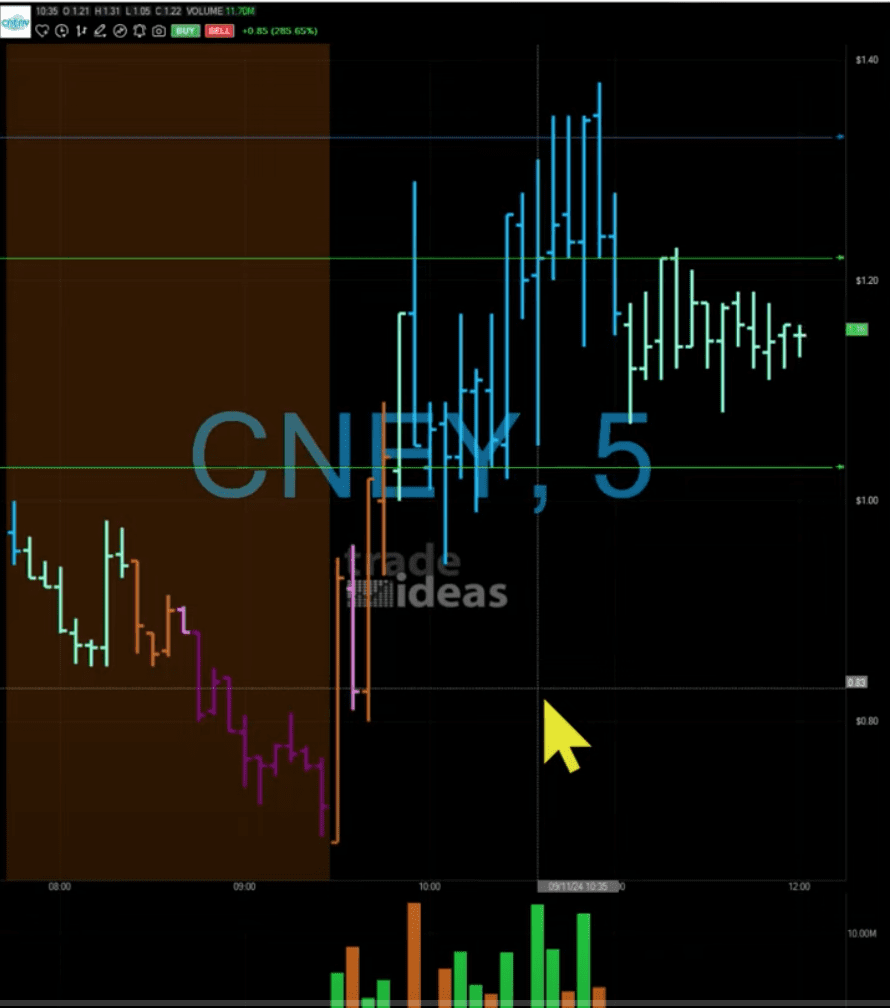

Read MoreWhat Makes This Trade Great: CNEY and the Art of Pattern Recognition

Hello, Barrie Einarson from Trade Ideas here, bringing you today’s edition of “What Makes This Trade Great.” To Subscribe: https://go.trade-ideas.com/SHQUse Promo…

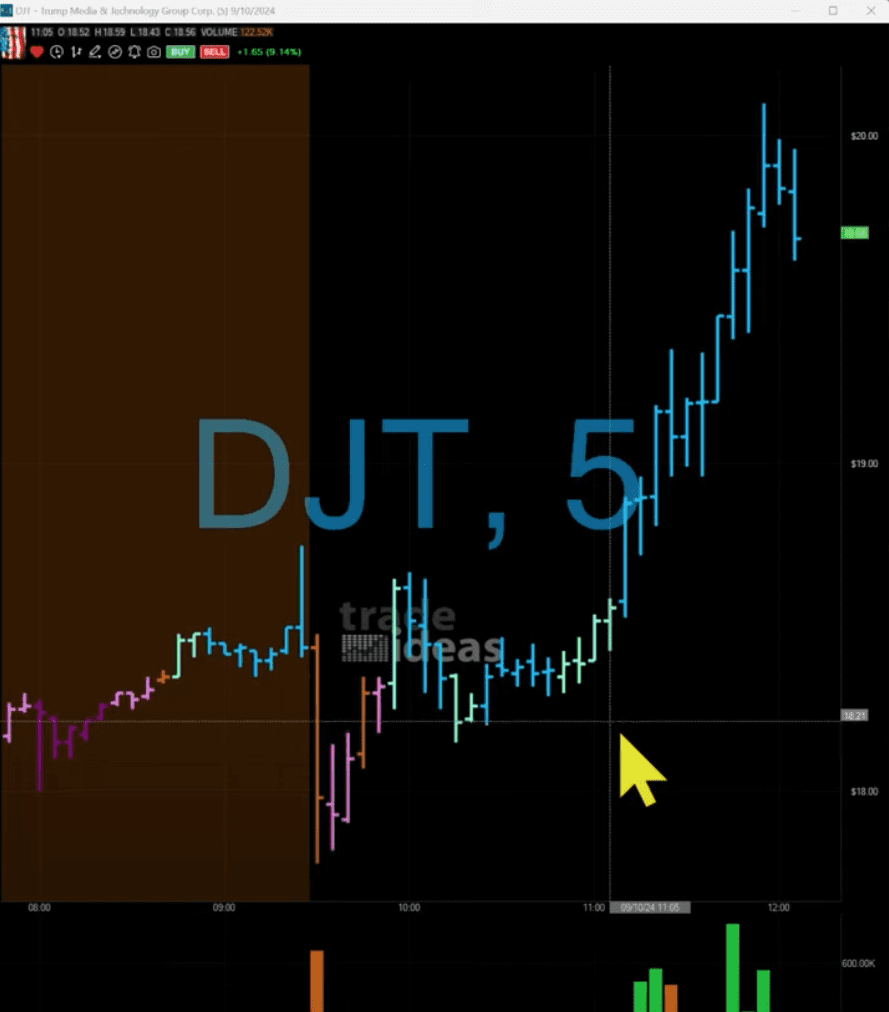

Read MoreTitle: What Makes This Trade Great: DJT Stands Out in a Choppy Market

Hello, everyone! Barrie Einarson here from Trade Ideas, and welcome to today’s edition of “What Makes This Trade Great.” Today,…

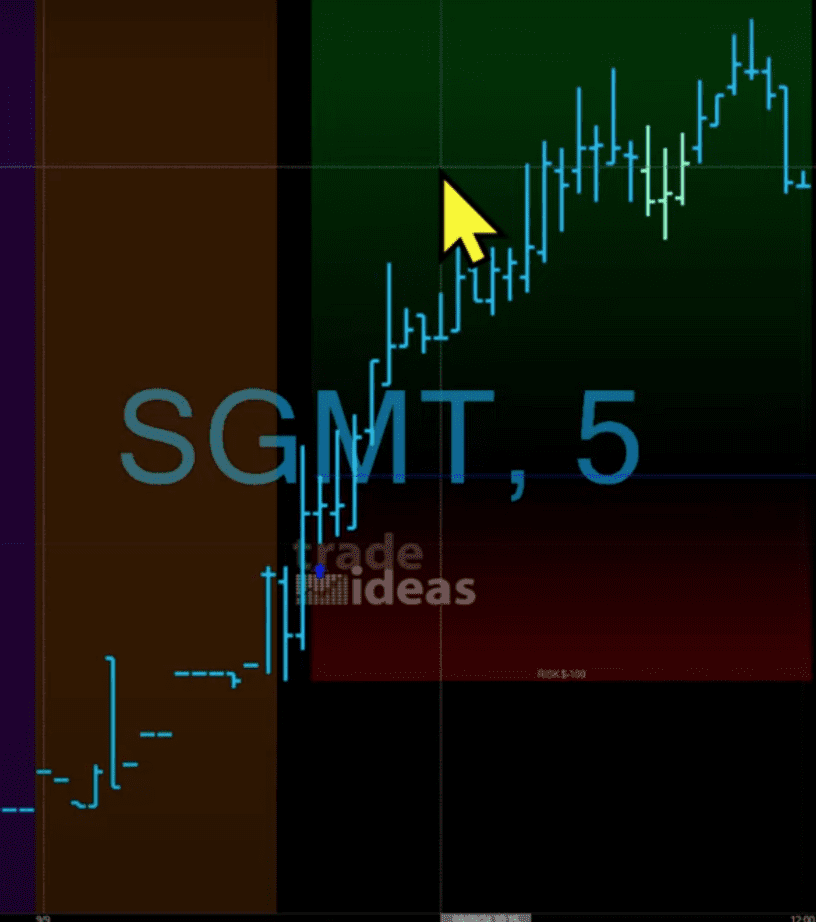

Read MoreWhat Makes This Trade Great: A Closer Look at Today’s SGMT Move

Hey, traders! Barrie here from Trade Ideas with today’s edition of “What Makes This Trade Great.” Let’s dive into another…

Read More